PRODUCTS > MINIHIL

miniHIL – Compact HIL solution for embedded system developers

Test your application after every code change.

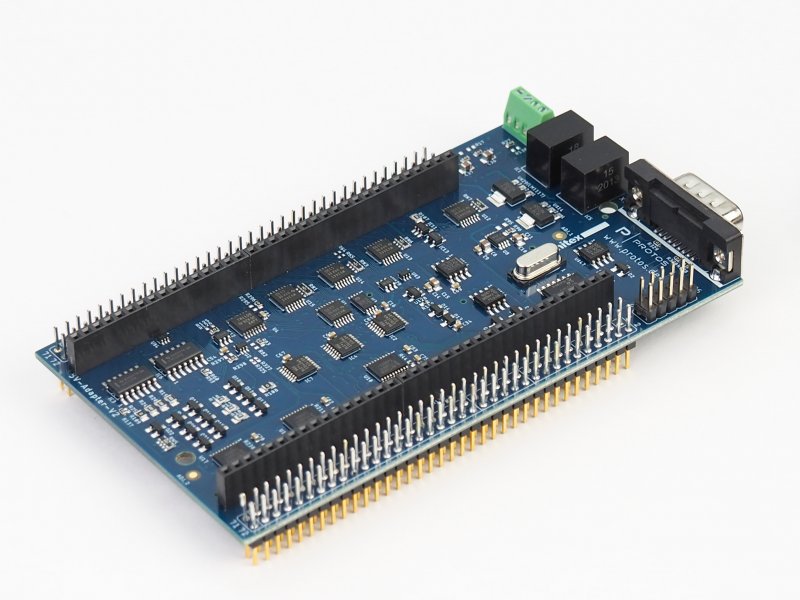

The miniHIL by PROTOS Software GmbH is a compact Hardware-in-the-Loop (HIL) testing solution designed for embedded software developers to test their applications early and continuously throughout the development process.

miniHIL Features

Test levels

- Component testing for drivers and low-level software

- Integration testing for embedded applications

- Simulated system test

- Acceptance test

Test system modeling

- Modeling test and simulation environments with eTrice

- Test case modeling and generation with CaGe

- Combinatorial test case generation with CaGe

- Adapter libraries for hardware interfaces

Reporting and Traceability

HIL test automation

- Test automation at the developer’s or tester’s workstation

- Test automation with Continuous Integration

- Command-line interface for test automation

- The technical documentation can be found in the miniHIL UserGuide .

miniHIL - Applications

Safety-Critical Applications

It is suitable for safety-critical applications across various industries including medical devices (blood glucose meters, insulin pumps), Industrial power tools (drills and their batteries), and automotive components (window requlator), where comprehensive and well-documented testing is mandatory.

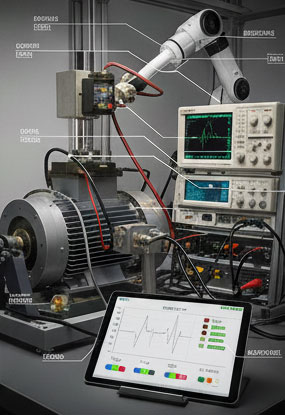

Motor Control Testing

Used for testing motor control software by simulating the motor and sensor signals to close the control loop.

General Embedded Systems

Applicable to any embedded system interacting with physical interfaces, allowing developers to validate software changes rapidly after every iteration.

miniHIL - Integration Testing Use Cases

The miniHIL is ideally suited for testing from the point where integration testing is required. Examples can be found here:

Microcontroller Applications

- STM32 systems

- Infineon TLE systems

- Other microcontrollers upon request

Driver Test

- Peripheral driver tests

- MCAL test for AUTOSAR

Motor Control Software

- BLDC and DC motor control

- Universal motor control

- Sensorless: Single Shunt / Dual Shunt

Environmental Simulations

- Sensor simulations (temp, acceleration)

- Battery and management simulations

- Component simulations (Flash, RAM)

Restbus Simulation

- CAN / LIN bus protocols

- TCP/IP, UART, XCP protocols

Miscellaneous

- Commissioning of MCU software

- Testing project-specific protocols

How does the miniHIL work?

- The miniHIL hardware connects the pins of the target microcontroller to the test system at the signal level.

- The miniHIL software is used to develop and generate test cases and environment simulations using models. These environment simulations (e.g., for motors, batteries, or bus protocols) are necessary to ensure the system under test (SUT) functions even without the actual system hardware. This allows the SUT to be quickly and easily deployed in a wide variety of situations, making the test for both successful and unsuccessful scenarios fully automated.

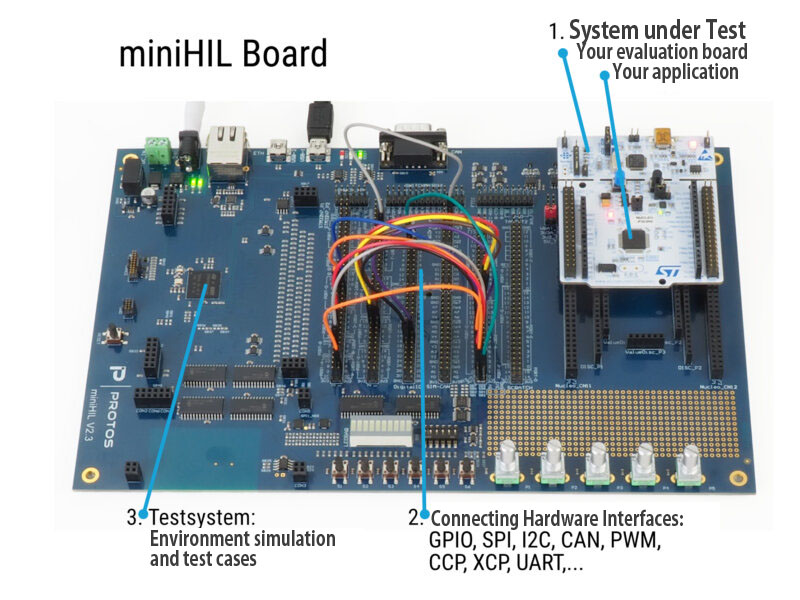

miniHIL Hardware Setup of a test system

- Plug in your evaluation board as a system under test. This ensures your embedded application is already running on the correct microcontroller. Examples of Target Microcontroller (System under Test):

- ST Microelectronics: STM32, STM8

- Infineon: TLE, AURIX, XMC

- NXP: S12

- Microchip: dsPIC33

- ARM Cortex-M

- and other processor platforms – Many adapters for conventional MCU development boards are already available, and we can develop new ones for other processors upon request.

- Connecting the hardware interfaces of the system under test to the test system.

- Is an interface or function missing? Simply add the miniHIL FPGA adapter.

- Development of environmental simulations and test cases running on a high-performance embedded processor (STM32H7).

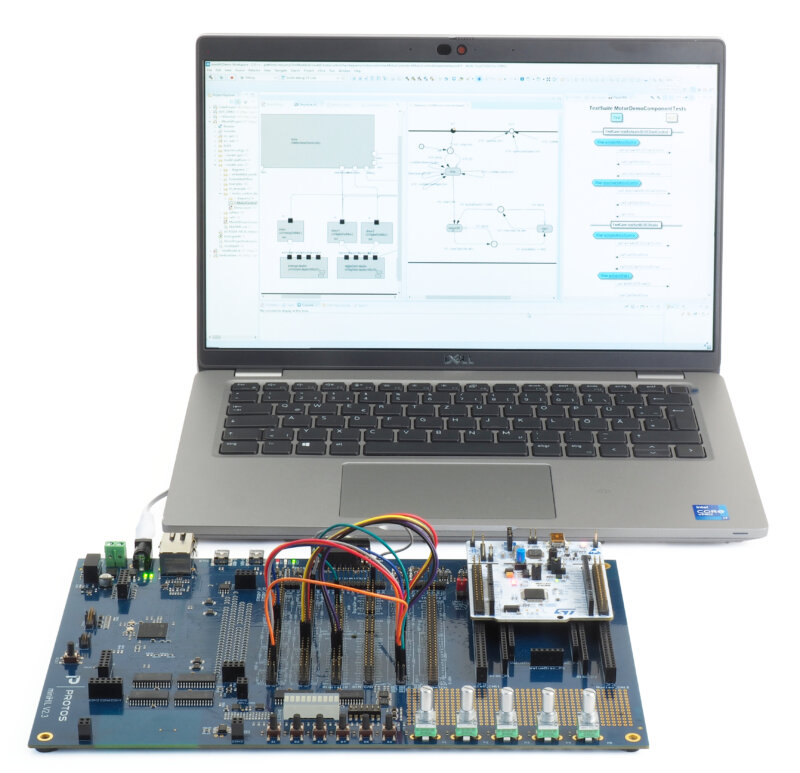

miniHIL Test Development

The tests and environment simulations for miniHIL are developed using a model-driven approach. The modeling is based on the open-source tool Eclipse eTrice, which enables structural and behavioral modeling and code generation. CaGe test models can be seamlessly integrated into the eTrice models. This combination allows for the easy creation of models that include both environment simulation and tests. The development environment requires a Windows PC with 8 GB of RAM and USB 2.0 ports.

A miniHIL model consists of the following parts:

- Adapter library for controlling the hardware interfaces (eTrice models)

- Simulation and monitoring elements that rely on the hardware interfaces (eTrice models)

- Your test cases can directly access the hardware interfaces as well as the elements for simulation and monitoring, e.g. for fault injection (CaGe models).

miniHIL Technical specifications

Hardware

- Power supply – 24 V DC power supply; 5 V and 3.3 V on the circuit board.

- Device Under Test (DUT) – Compatible with STM32 Nucleo and Arduino-format boards. Adapters available upon request.

- Test System Processor – STM32H743 MCU.

- Interfaces and I/O – 18 analog outputs; 8 analog switches, 16 digital GPIOs; 2 controllable power supplies (brown-out testing).

- Debugger – Integrated ST-Link for test system processor.

- DUT Input/Output – 5 rotary potentiometers; 13 LEDs; 6 push buttons; 6 DIP switches; CAN interface; 4 USB-to-UART interfaces.

- Further content – wire bridges and USB cables

Software

- eTrice – Eclipse-based development environment for the miniHIL.

- CaGe – a programming language for modeling test cases.

- SimModelLib – Test and Platform Library.

- SimRuntime – Runtime environment for the tests.

- Cube Project – Example project, suitable for the integrated STM32H743 MCU.

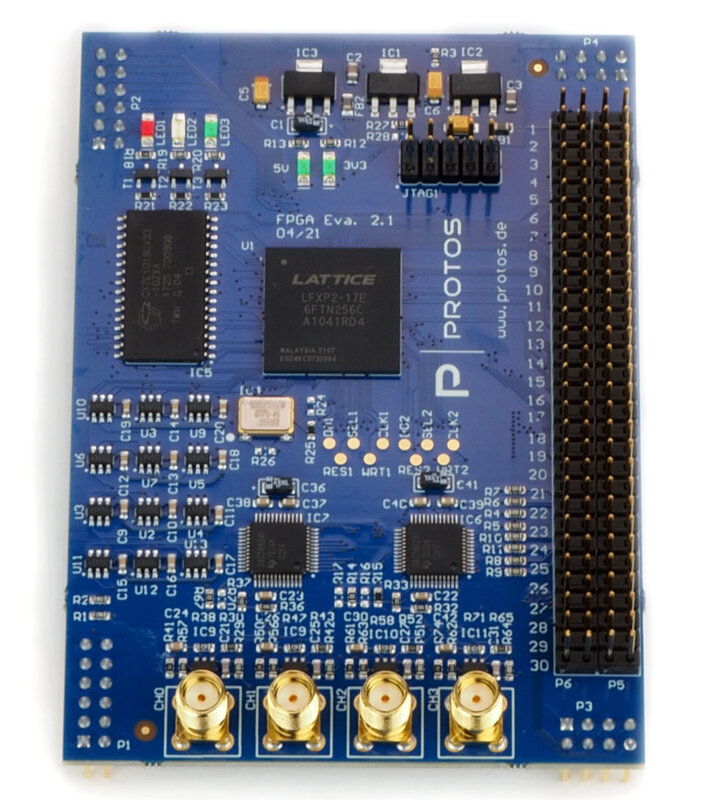

miniHIL extension: FPGA Adapter

Some test approaches require faster data conversion, specially configured interfaces, or significantly more digital I/Os. The miniHIL FPGA adapter, based on the Lattice LF-XP2-17e, can generate analog signals using 8- or 12-bit DACs. It also provides 89 configurable digital pins. These enable fault injection, CRC or protocol testing, setup checks, the implementation of alternative bus protocols, and the simulation of signals with sub-microsecond response times.

The FPGA is programmed using Lattice Diamond , a user-friendly, powerful design tool for FPGAs. Alternatively, the PROTOS team will gladly assist you in developing your test environment.

- Lattice LF-XP2-17e

- 89 digital I/Os – 0.0V to 3.3V

- 4 x 12-bit DACs – > 10 MHz

- 12 x 8-bit DACS – > 200 kHz

- Dual QSPI connection to the miniHIL

- 17,000 LUTs

- 35 KBits Distributed RAM

miniHIL extension: Adapter Boards

The miniHIL supports most boards that follow the pinout of boards like Arduino or STM32 Nucleo . The PROTOS team can also offer support in the design and development of custom adapter boards. Some boards already exist, such as our generic 5V adapter board, as well as boards for the Infineon TLE987x motor driver with integrated Arm Cortex M3 or Microchip’s dsPIC33EV .

- Our generic adapter offers:

- 15 x analog level shifters (output: 0-5 V)

- 12V supply voltage with current measurement (for powering the target MCU)

- 5V and 3.3V power supply for target board

- 2 x analog outputs 0-30 V

- 22 x bidirectional level shifters 3.3 V <-> 5 V (digital)

- 4 x digital 5V outputs with enable (for tristate signals)

- 1 x LIN Out (via Lin Transceiver)

- 1 x MCP2518FD (Connected to miniHIL MCU for additional CAN interface)

- 1 x CAN Phy (used by target or miniHIL MCU)

- Motor bridge with gate signal adaptation for measuring the gate signals at 3.3 V + provision of U_DS measurement signals.

- Analog multiplexer for PWM-synchronous provision of single shunt signals

Customer Testimonials

KÄRCHER uses the miniHIL test system from PROTOS to test software efficiently and automatically. This enables fast, comprehensive testing of all product variants – from pressure washers to other cleaning systems.

Eclipseina develops charging communication solutions and uses eTrice to efficiently model the architecture of its charging controller product line. This enables consistent software, automated code generation, and flexible product variants, saving time and costs.

Fleckner + Simon optimizes automotive testing with PROTOS’ miniHIL to reduce costs and shorten development times. Developers gain access to their own test systems, automated tests, and efficient error analysis. F+S supports customers with implementation, ISO 26262 qualification, and integration with Polarion ALM.

Hitex develops embedded hardware and software for various industries. The miniHIL test system enables faster, more cost-effective, and standardized testing of projects without the need for complex modifications. Hitex also supports customers in implementing the system.

Dainese relies on PROTOS’ miniHIL for testing its D-Air® airbag technology. This allows algorithms to be tested automatically, quickly, and reliably – from MotoGP data to everyday scenarios. This prevents false deployments and ensures certification.

“Groundbreaking – the testing system even fits in a backpack.” Nicolò Bargellesi, Dainese